Call us now

08045478882Rotational Moulding Arm Machine

Minimum Order Quantity : 1 Pieces

Delivery Time : 7-10 Days

Warranty 1 Years

Type Rotational Moulding Arm Machine

Material Mild Steel

Computerized Yes

About this product

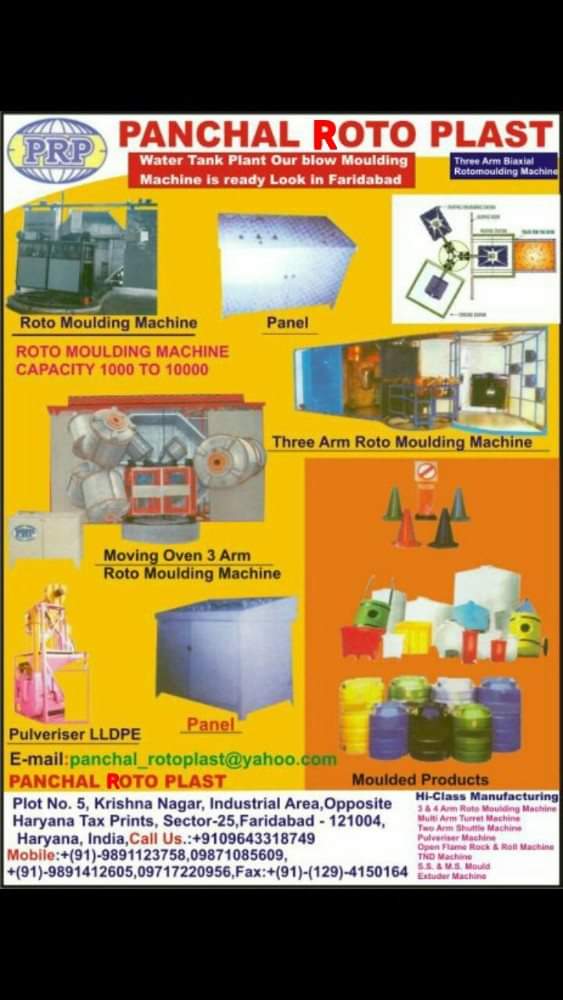

Three arm biaxial roto moulding machines

1900000 INR/Unit

Minimum Order Quantity : 1 Units

Delivery Time : 2 Months

Warranty 1 Year

Type Roto moulding machines

Material All types of plastic material mfg.

Computerized Yes

Capacity 500 ltr. , 1000 ltr. , 2000 ltr. , 5000 ltr. Ltr/hr

Automatic Grade Semi-Automatic

Sample Policy Free samples are available

Sample Available Yes

Payment Terms Cheque, Cash in Advance (CID)

About this product

Three arms bi-axial are three station machines with fixed turret and fixed oven. These are most versatile rotational moulding machine and most suited for high volume production. Cost of production is lowest for entire range of production.

Advanced Computerized Control

This three arm biaxial roto moulding machine is equipped with computerized systems to streamline operations and improve process accuracy. The digital interface simplifies monitoring and parameter adjustments, making it suitable for manufacturers seeking consistent quality and efficient management. Computerization enhances productivity and minimizes manual errors.

Flexible Capacity Range

With production capabilities of 500, 1000, 2000, and 5000 liters per hour, the machine offers options tailored to small, medium, and large-scale manufacturers. This flexibility supports diverse production demands and allows businesses to scale operations easily without major equipment changes.

Versatile Material Processing

Designed to process all types of plastic materials, this machine meets a wide array of manufacturing requirements. Whether producing tanks, containers, or custom products, its adaptability ensures manufacturers can respond quickly to market trends and customer needs.

Advanced Computerized Control

This three arm biaxial roto moulding machine is equipped with computerized systems to streamline operations and improve process accuracy. The digital interface simplifies monitoring and parameter adjustments, making it suitable for manufacturers seeking consistent quality and efficient management. Computerization enhances productivity and minimizes manual errors.

Flexible Capacity Range

With production capabilities of 500, 1000, 2000, and 5000 liters per hour, the machine offers options tailored to small, medium, and large-scale manufacturers. This flexibility supports diverse production demands and allows businesses to scale operations easily without major equipment changes.

Versatile Material Processing

Designed to process all types of plastic materials, this machine meets a wide array of manufacturing requirements. Whether producing tanks, containers, or custom products, its adaptability ensures manufacturers can respond quickly to market trends and customer needs.

FAQs of Three arm biaxial roto moulding machines:

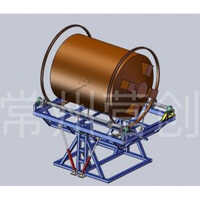

Q: How does the three arm biaxial roto moulding machine operate?

A: The machine rotates on two axes to evenly distribute molten plastic inside the mould, resulting in hollow products with uniform wall thickness. It is semi-automatic and computerized, requiring minimal manual intervention for efficient operation.Q: What types of plastic materials are compatible with this machine?

A: This machine is built to process all kinds of plastic materials, making it versatile for various applications in the plastic manufacturing sector.Q: When should I consider choosing a semi-automatic machine over a fully automatic model?

A: A semi-automatic machine offers a balance between manual control and automation, making it ideal for manufacturers who require flexibility and customized production but still desire the benefits of some automation and computerized precision.Q: Where is this three arm biaxial roto moulding machine manufactured and supplied?

A: This machine is manufactured and supplied in India, catering to both domestic and international clients seeking robust plastic manufacturing solutions.Q: What is the process of using this machine for plastic product manufacturing?

A: The process involves loading the mould with plastic material, which is then heated and rotated biaxially to ensure even material distribution. After cooling, the product is removed, and the cycle is repeated, ensuring consistent quality and productivity.Q: How can manufacturers benefit from using this machine?

A: By using this machine, manufacturers gain improved production efficiency, versatility in processing different plastics, scalable output capacities, and the advantage of computerized controls for precise and reliable outcomes.Explore Additional Categories

Contact Us

Our Products

Our Products